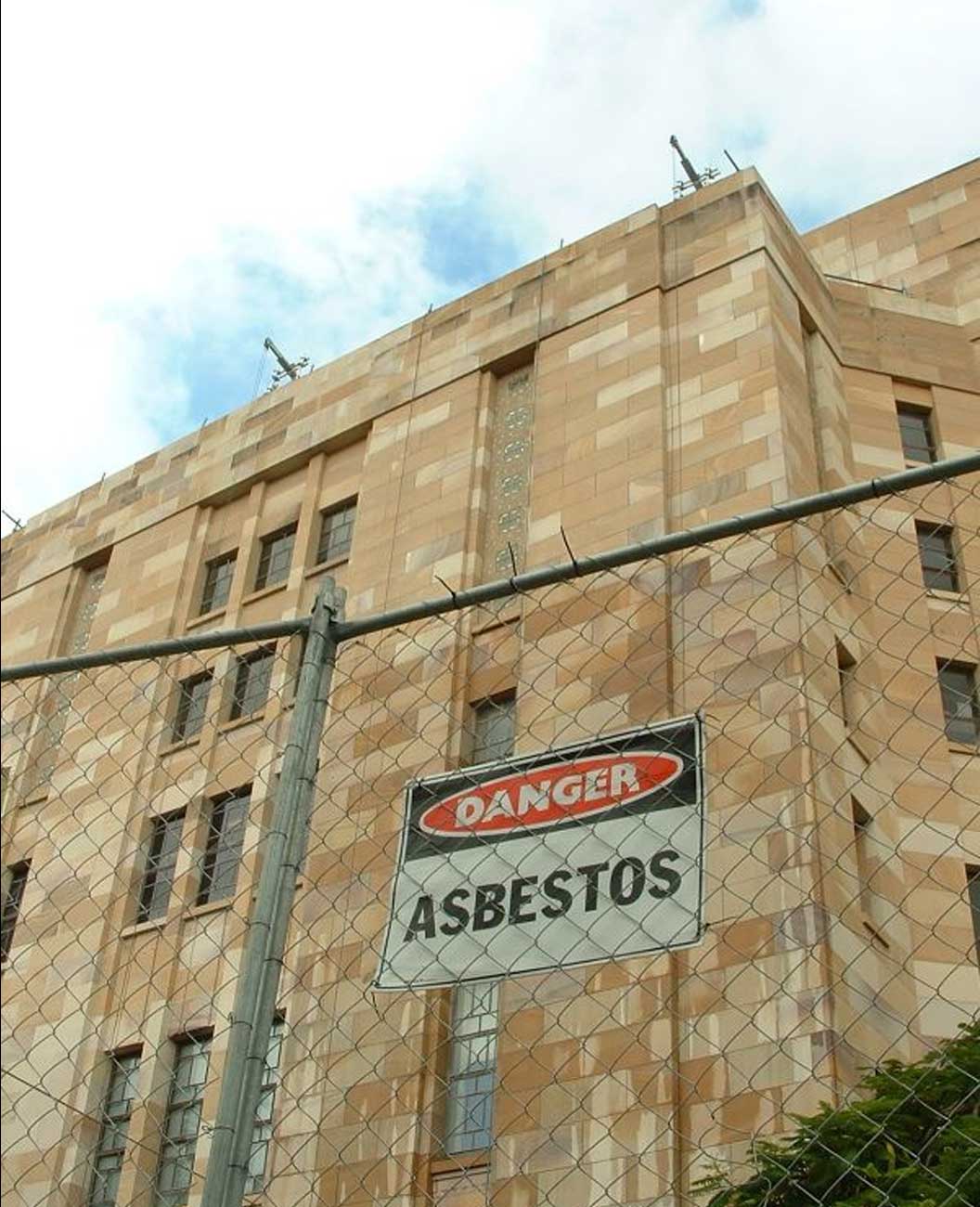

Reliable Asbestos Inspections by Accredited Asbestos Consultants

An asbestos inspection by a qualified asbestos consultant is recommended to ensure that the most accurate results are obtained. The biggest risk in undertaking asbestos sampling by yourself is not knowing exactly what materials may contain asbestos. Asbestos inspections should be done by a qualified asbestos consultant who will identify those materials likely to contain asbestos. In the process they will take samples and analyse if the material contains asbestos and most importantly to conduct a risk assessment of the material based on the likelihood of the material to liberate fibres under the current conditions.

The three main types of asbestos inspections include:

- Management inspections;

- Refurbishment & demolition inspections; and

- Clearance Inspections

Management Inspections

The primary focus on an asbestos management inspection is to identify Asbestos Constraining Materials (ACM) within the building and provide a risk assessment of those suspected materials. The inspection is conducted by an asbestos consultant who will walk through and identify as much as can be reasonably practicable the building element that may contain asbestos. The materials are placed into the asbestos register with a risk assessment, location and photos to depict what the ACM look like. Management asbestos inspections include the following:

Presumptive asbestos inspections presume that the material contains asbestos whereas sampling asbestos inspections require that the asbestos consultant samples suspected asbestos materials. The samples are analysed at the NATA laboratory to determine if asbestos is detected and the type of asbestos that it may contain.

Not all suspected materials will contain asbestos. This may depend on the building age, type and method of construction. In most instances there commonly is between 40 – 80 % of the suspected building elements containing asbestos. Sampling inspections are more expensive to begin with due to the cost of asbestos testing, management asbestos inspections which include sampling are more cost effective in the long run as those materials which do not contain asbestos can be treated as not being a significant risk which may save money in the long run due to maintenance, repairs and finally demolition which can incur significant expense.

Asbestos Inspections During Refurbishment and Demolition

Refurbishment and demolition inspections are carried out to identify and remove asbestos materials to eliminate the risk of exposure to workers and the surrounding environment. Sampling is conducted to determine if the building material or element contains asbestos. The inspection involves partial destruction of the finishes whilst people are not in the building, prior to the actual demolition or refurbishment.

Refurbishment and demolition inspections are required even if a management inspection have been carried out. This is due to the refurbishment and demolition inspections being a more intrusive inspection of the building. The cavities of walls and ceilings not normally able to be accessed will be looking into where possible to identify these hidden materials.

If the refurbishment & demolition inspections aren’t conducted, there is the risk that builders or trades could cut through and disturb these hidden materials until it’s too late during a renovation.

Clearance Inspections

A clearance inspection is conducted after asbestos has been removed and a competent person deems that the area is safe to re-occupy. There are two main types of asbestos inspections to determine whether the area is clear of asbestos. This is depending on whether the material is considered:

- Non-Friable (NF) asbestos; or

- Friable Asbestos (FA).

Non-friable asbestos is also commonly called bonded asbestos and is a relatively stable form of material. Clearance inspections after the removal of non-friable (bonded) asbestos generally includes a visual inspection to ensure that there is negligible ACM remaining.

The asbestos clearance inspection of friable material requires air monitoring to be undertaken as well as the visual examination. In the majority of friable removal work, an enclosure or bubble is required to minimise the release of asbestos fibres in to the air. Prior to the enclosure being dismantled, an inspection and air monitoring must also be undertaken before allowing people to re-occupy the area.

Asbestos inspections should be conducted by competent inspectors

Asbestos Check recommend that only inspection bodies accredited by the National Association of Testing Authorities (NATA) be engaged to undertake asbestos inspections. Complying with the requirements of AS/NZS ISO.IEC 17020 (2000). Asbestos Check is a Type A inspection body accredited by NATA (accreditation No: 17139)

Safe Environments conducts asbestos inspections in Sydney, NSW, Victoria, Melbourne, ACT and Canberra (ACT Class A Asbestos Assessors: Farzad Jalali, license #2010268; Carl John Strautins, license #2007521). IN the ACT & Canberra only, licensed Class A or Class B Asbestos Assessors can undertake asbestos inspections and surveys.

Safe Environments asbestos reports are produced in accordance with the requirements of the National Occupational Health and Safety Commission Code of Practice for the Management and Control of Asbestos in Workplaces [NOHSC:2018(2005)].

Be absolutely assured. Safe Environments is NATA accredited for asbestos Inspections and preparing asbestos management plans.